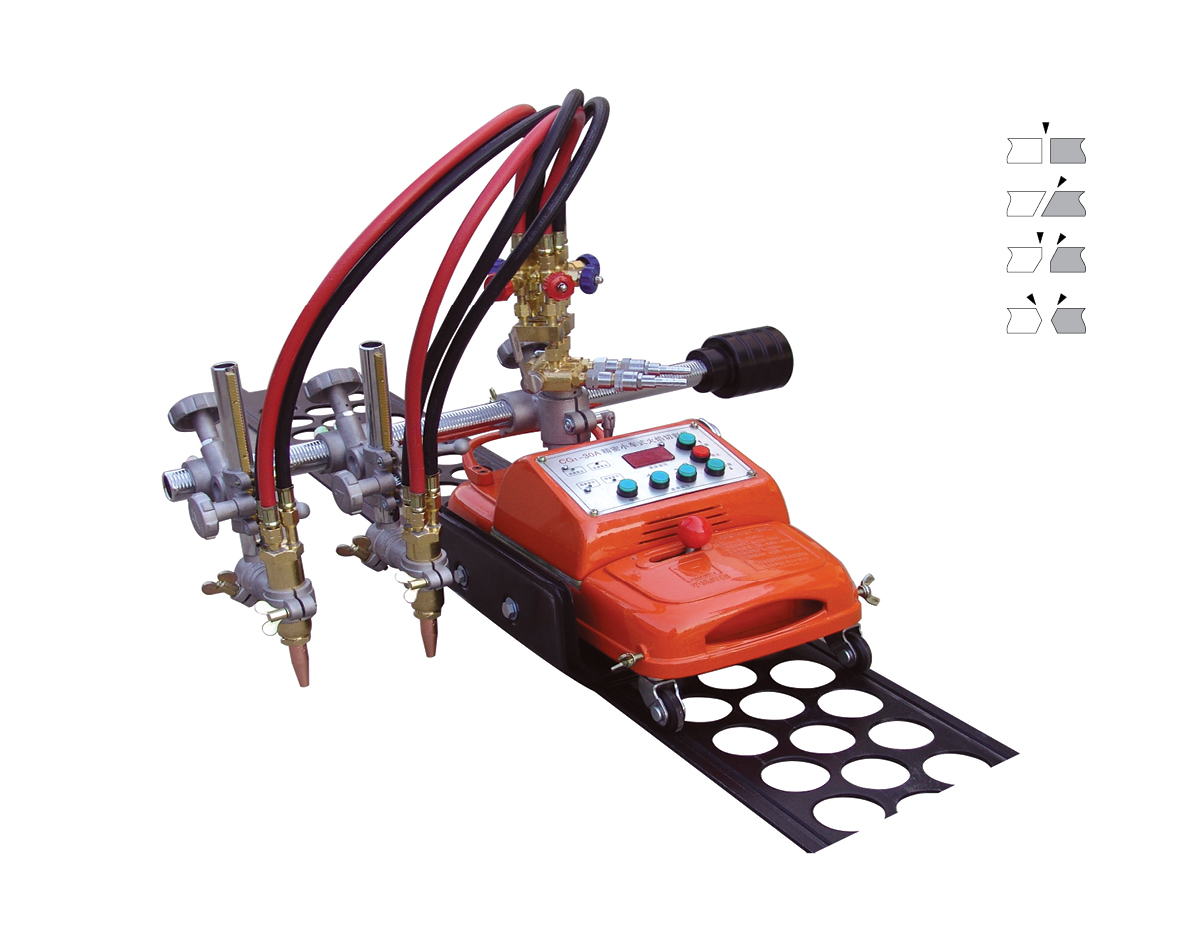

Two Torches Steel Straight Line Gas Cutting Machine

Introduction

“CG1-100A” gas cutting machine is one of main products of our company. It is designed well and beautiful. We adopt many advices of customers and hold technical seminars. Then, we do technical innovations and optimizations for it. This machine adopts new material, which improves the serviceability, durability and heat-insulating property.

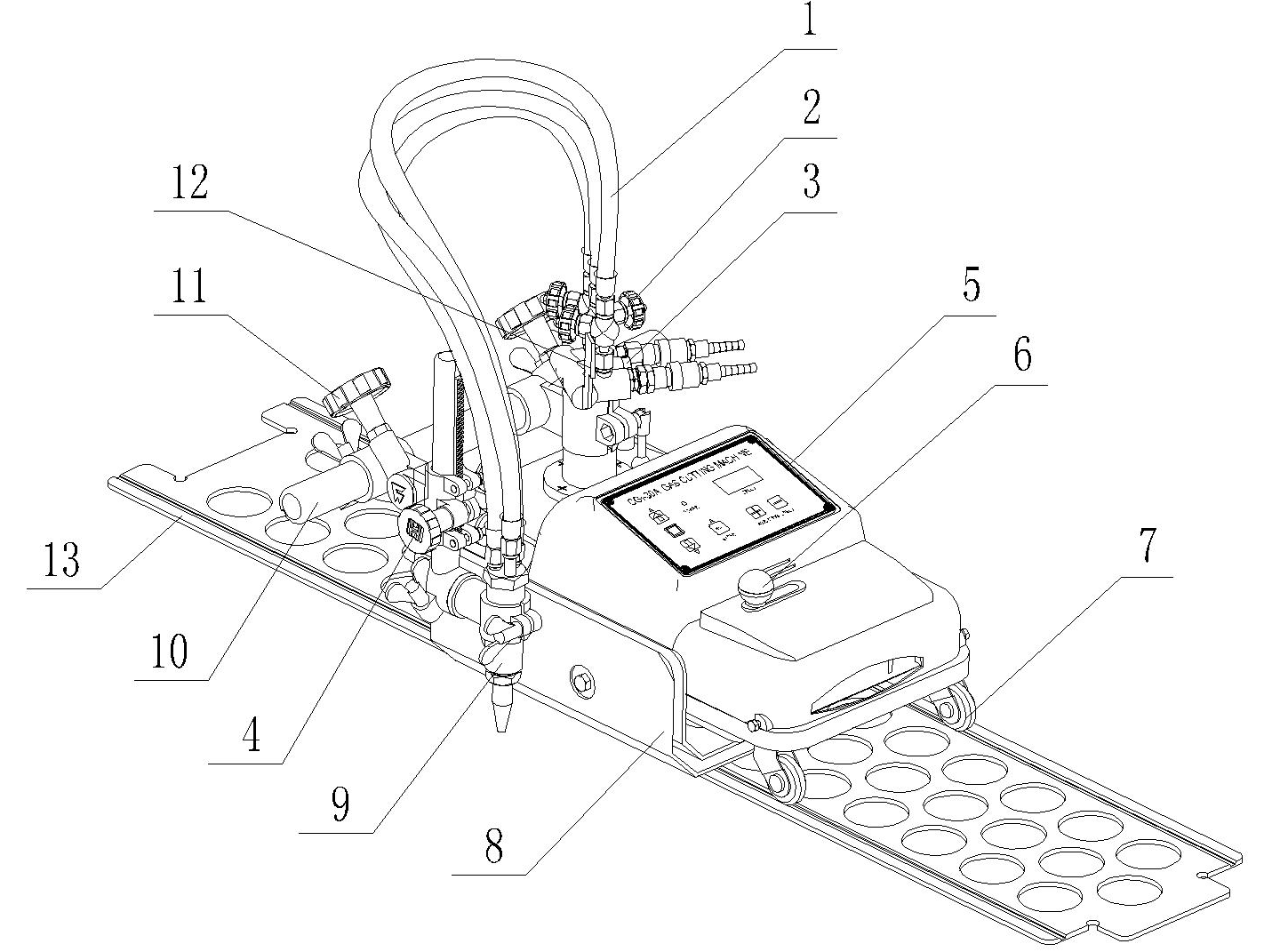

Structure

1. Hose: Connect them between distributor and torch. The three hoses are used individually for fuel gas, preheating oxygen and cutting oxygen.

2. Gas two-way valve: To adjust gas-flow rate.

3. Gas distributor.

4. Hand wheel: To adjust the up-down distance of torch by the wheel.

5. Main machine.

6. Clutch hand knob

7. Universal wheel

8. Thermal baffle: To prevent the heat diffusing into the inner of machine.

9. Torch body.

10. Cross gear rack

11. Cross hand wheel: To adjust the horizontal distance of torch on cross bar.

12. Fast switch knob: The knob is divided into three grapes: “close”, “preheating oxygen” and “cutting”. It will close all the gas valves if the knob is on the “close” position.

13. Guide rail: There are two types: convex wheel and concave wheel.

Technical parameter

Weight | 25.5kilograms |

Machine dimension | 430mm×230mm×280mm |

Speed control | Integrated circuit |

Power source | AC 220V 50HZ |

Cutting speed | 50~750mm/min |

Cutting thickness | 8-100mm |

Groove angle | 0-45 degree |

Diameteral of cutting circle | ø200-ø2000mm |

Tip | G02 1#、2#、3# |

Motor | DC 110V 0.5A 30W 3600-4600r/min |

Convex guide rail | 6Kg(2pc) |

Concave guide rail | 8Kg 1.8m/pc or 11Kg 1.2m/2pc |

Picture for reference