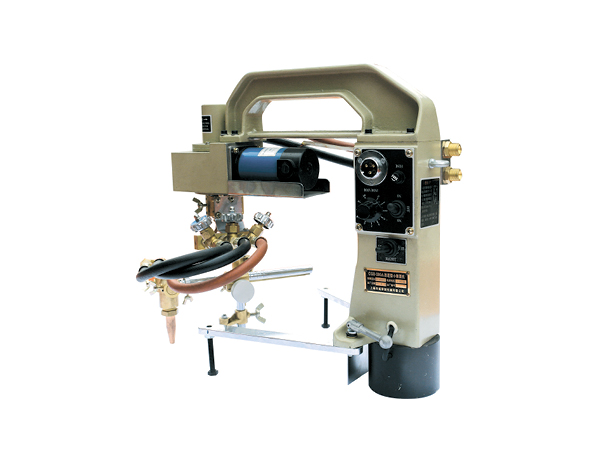

High Accuracy Small Diameter Cycle Gas Cutter For Max. 30mm Steel Plate Cutting

Introduction

“HK-200”circlular gas cutter (Revised) has high strength magnet at the bottom, which can stick to the steel plate completely. So, it can do circle cutting on incline or vertical. The system adopts rotary gas distributor to avoid hoses enwinding. It can do groove cut.This machine is portable. It is equipped with locating device of center of circle and the operation is very easy and flexible.

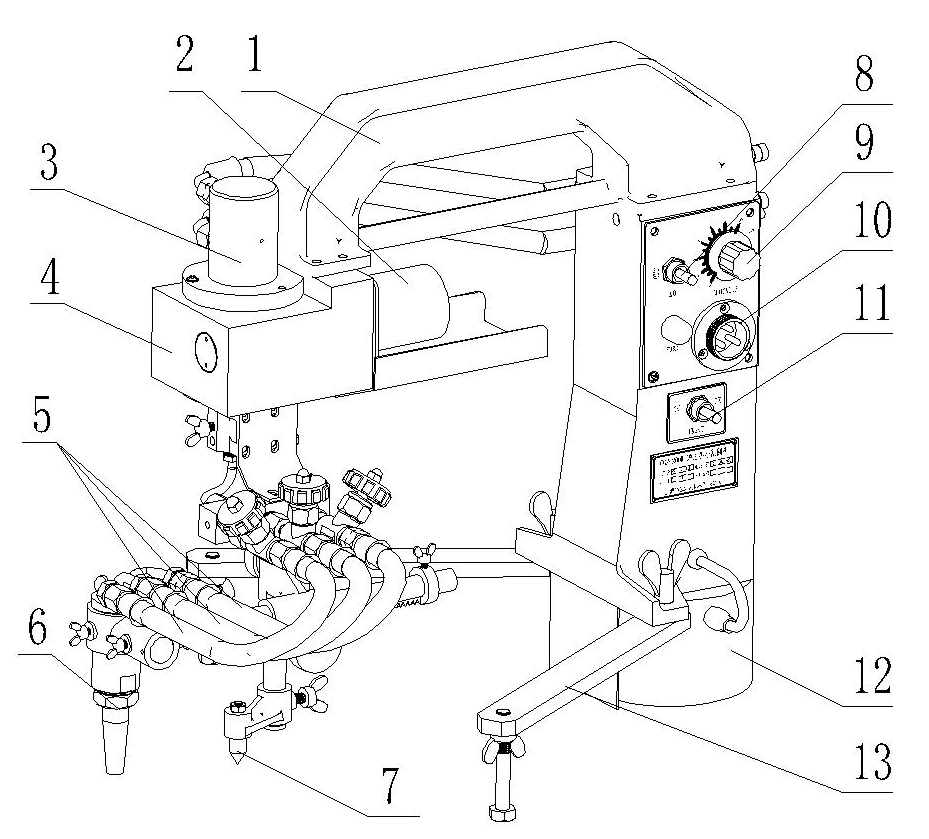

Structure

1. Handlebar

2. Motor

3.Rotary gas distributor: To avoid the hoses enwinding in the process of cutting.

4.Gear case

5. Hoses

6. Torch

7.Center: The center should be put in the punched hole, which is on the center of circle.

8.Reversing switch of motor: To change the direction of cutting. The “STOP” position is in the middle.

9. Hand wheel of adjusting speed : To adjust the speed of machine.

10. Outlet

11. Electromagnet switch

12. Electromagnet

13. Supporter: To maintain the balance.

Technical parameter

1. Weight(Body) | 11.5 kilograms |

2. Machine dimension | 450(L)×395(H)×360(W)mm |

3. Speed control | SCR control |

4. Power source | AC 220V±10% |

5.Rotary speed of torch | 0.5~6.5 r/min |

6. Cutting speed | 5-30mm |

7. Groove angle | 0~45° |

8.Diameteral of cutting circle | Φ40~Φ200mm |

9.Gas | Suit for oxygen, acetylene or liquefied petroleum gas |

10.Motor | DC 24V 15W 5000r/min |

11.Fixed mode | Electromagnet (Adsorption affinity :150Kg/0mm) |

Picture for reference