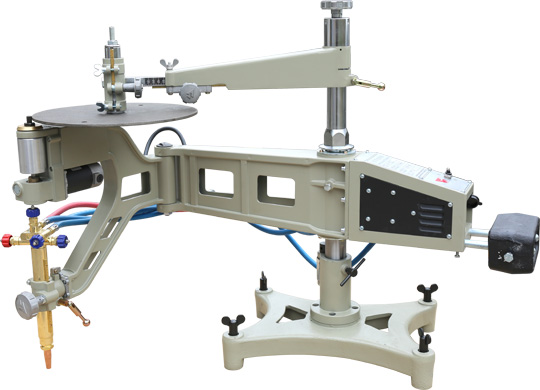

High Efficiency Profiling Flame Shape Cutting Machine For Carbon Steel Cutting

Introduction

"CG2-150" contour cutting machine is a new product of efficient and economical cutting machine, the internal structure of the machine is designed reasonably; Beautiful appearance and generous. The body is made of precision die-casting aluminum ingot. According to the template can cut a variety of parts graphics, cutting surface quality is good, high precision, suitable for mass production of the same shape cutting parts. The fuselage is small and the cutting range is wide, which is not only suitable for enterprise factory use, but also suitable for field work. In addition to applicability, it also has many advantages: the speed control system uses a superior thyristor rectifier with the following characteristics: it can speed evenly within the specified range, without changing the motor performance, and the speed control is also stable. With a small control voltage, the motor speed can be direct, and the control energy loss is small. The heating of the electrical system has little effect on the motor, long service life and easy maintenance. The cutting torch is located under the base arm, and when the base arm moves along the edge plate of the template, the cutting torch can correctly cut the same shape as the template.

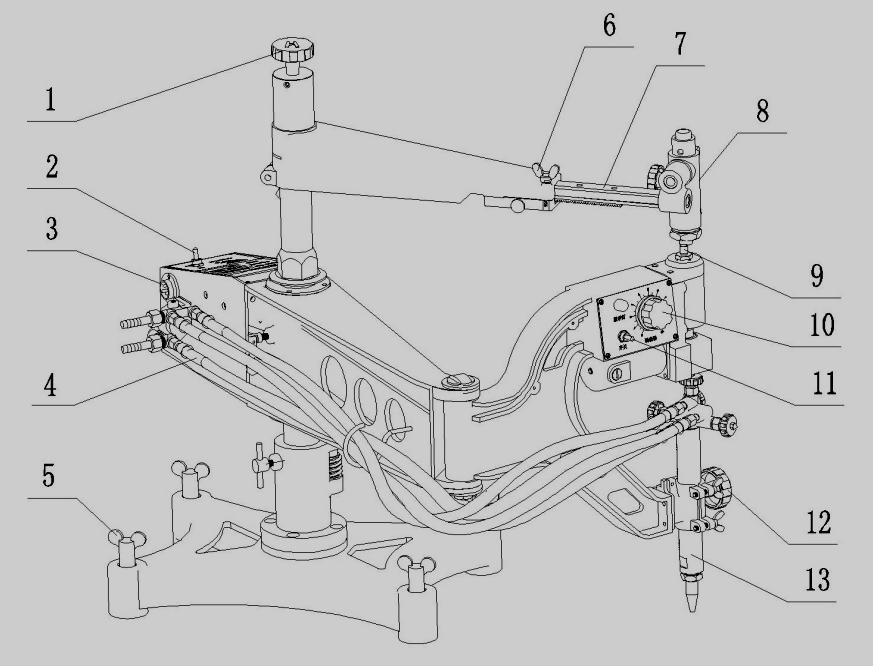

Structure

1. Lift wheel of arm: Release the screw of arm and adjust the wheel to make the arm unit assembly rise or fall.

2. Power switch

3. Power outlets

4. Gas conveying hose: installed between the distributor and the cutting torch, a total of four. Divided into preheating oxygen, cutting oxygen, gas and pressure switch gas supply.

5. Foot screws: adjust the machine level on the steel plate

6. Locking screw of the transverse arm: when the position of the template is selected, the transverse arm is locked in the shape arm through the locking screw.

7. Transverse rod: The cross section of the transverse rod is provided with a ruler, which can be adjusted horizontally according to the scale of the template.

8. Template frame: used to fix the template, but also can vertically adjust the height of the board.

9. Magnetic head

10. Speed control knob: Rotate the knob in the direction of "10" to speed up the device movement.

11. Direction adjustment switch: change the rotation direction of the machine magnetic head.

12. Cutting torch lifting hand wheel

13. Cutting torch

Technical parameters

Weight (main parts) | 56.5kg |

Dimension | 1190*335*800 mm |

Speed control | Silicon Controlled Rectifier (SCR) Control |

Power Supply | 220V 50HZ |

Cutting speed | 50-750/mm/min |

Cutting thickness | 5-100mm |

The diameter of cutting circle | φ20-φ600mm |

Cut straight lengths | 1200mm |

Square size of cutting | 400*900mm, 450*750mm |

Motor | 55/ZYT DC110V24W rotation speed 3600r/min |

Picture for reference